the pipe repair clamp manufacturer will show you how to install pipe clamps effectively and reasonably

publishing time:

21-04-27 09:33

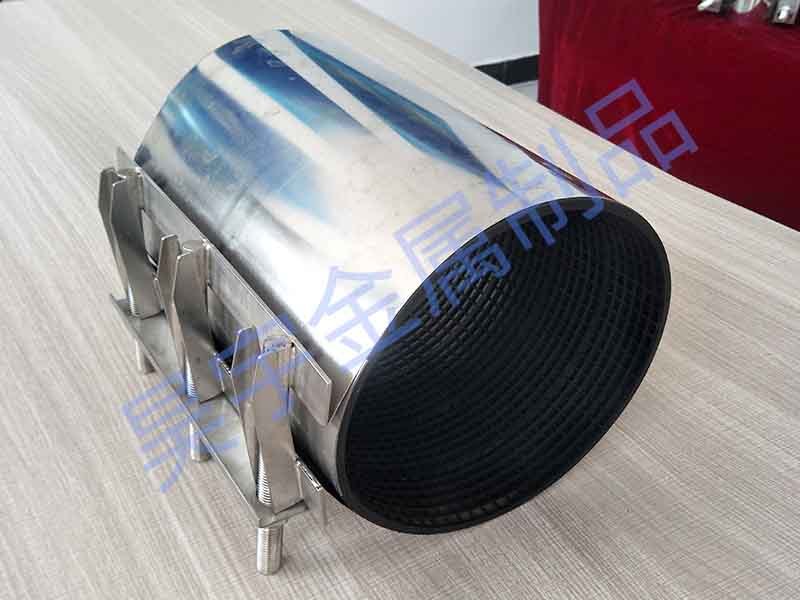

1. the pipe repair clamp manufacturer tells you that before assembling on the welding board, in order to determine the direction of the chuck, it is recommended to mark the chuck at a fixed position. the pipe repair clamp manufacturer tells you to then weld, insert the lower part of the chuck valve body, and fix the pipe in it. place the pipe clamp and the other half of the cover plate and nail them tightly. do not directly weld the chuck bottom plate.

2. the pipe repair clamp manufacturer tells you that when installing the rail on the ground, the rail can be welded to the base or fixed with screws. then push the rail nut into the rail and rotate it 90 degrees. the manufacturer of pipe repair clamp tells you that the lower half of the pipe clamp is embedded in the nut, and the fixed pipe clamp and cover plate need to be installed on the upper half of the pipe clamp and fixed with screws.

3. laminated components. the pipe repair clamp manufacturer tells you that the guide rail can be welded to the base or fixed with screws. first install the upper and lower halves of the pipe clamp, and then install the upper part of the pipe clamp on the pipe that needs to be fixed, and fix it with screws to prevent it from rotating with the anti-loosening cover. the pipe repair clamp manufacturer tells you to install the two pipe clamps as described above.

4. the pipe repair clamp manufacturer tells you that when assembling the curved pipe, the pipe should be directly fixed before and after the curved pipe with a pipe clamp. some people suggest that such a support point should be a fixed location.

preceding line

next article

other news

application scope of sanitary stainless steel clamp

the structure of the sanitary stainless steel clamp is specifically a combination of two stainless steel wires. the clamp joint is an annular clamp joint surrounded by two stainless steel wires. sanitary stainless steel clamp has the characteristics of beautiful appearance, convenient use, strong clamping force and good sealing performance.

what are the advantages of high pressure pipe repair clamp

what are the advantages of high pressure pipe repair clamp? quickly install pipes with high pressure pipe repair clamp and corresponding pipe fittings. no welding is required during construction, no need to re-galvanize and re-assemble. the assembly efficiency is improved.

how to deal with high pressure pipe repair clamp in bad condition

as a tool for repairing pipelines, high pressure pipe repair clamp has installation methods and steps, but in many cases, in order to repair faster, it is easy to omit some steps, resulting in bad conditions. how to do it? let's find out together!

how to deal with the daily problems of straub double lock clamps

leakage of straub double lock clamps is a very troublesome problem. in daily life, this kind of problem often troubles us. so how should we prevent these problems? today we will explain to you.

what should be paid attention to when using straub double lock clamps

straub double lock clamps are connection tools between pipes and pipes, and are detachable connection points between components and pipes. it plays an indispensable and important role in pipe fittings, and it is one of the two main components of hydraulic pipelines.

what are the ways to use stainless steel pipe coupling

there are many ways to use stainless steel pipe coupling, so what are the ways of using stainless steel pipe coupling that we can understand in engineering construction? let's talk about it in detail today.